Drive systems

In 1999 Keestrack introduced a load sensing diesel/hydraulic drive system which resulted in 25% fuel savings compared to competition.

Already in 2012 Keestrack brought the full electric plug-in drive to market, backed up by an onboard diesel/generator. The first machine with electric drive was the C6e classifier.

Since then, Keestrack has introduced e-drives throughout the entire product range which all have plug-in and plug-out functionality to power ancillary equipment.

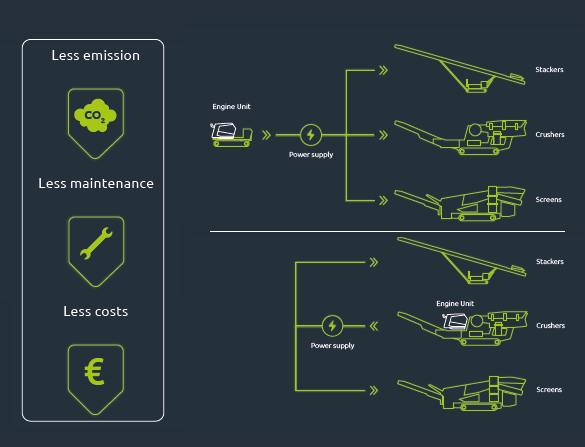

The on-board diesel/generator evolved in the drop-off engine gensets of the crushers. Which can be placed on the frame of the machine or besides the machine in a less dusty and vibrant environment.

In 2021 the drop-off gen-set became available as a tracked engine/genset, (Keestrack M-series) to power connected Keestrack crushers, screeners, and stackers directly with electricity in case there is no plug-in connection from the grid available. This way the economic advantages of the complete production train will rise due to using only one engine for several machines.

-

Flexibel

Alle elektrisch aangedreven machines kunnen met elkaar geconnecteerd worden voor stroom, indien nodig ondersteund door een generator.

-

Altijd operationeel

Kan worden gevoed via het net via de plug-in-aansluiting of door eender welke beschikbare generator waardoor de eindgebruiker minder afhankelijk is van een specifieke motorleverancier.

-

Kostenbesparingen

Minder onderhouds- en operationele kosten.

-

Duurzaam

Aangedreven met hernieuwbare energie, volledig koolstofvrij.

ZERO-drive

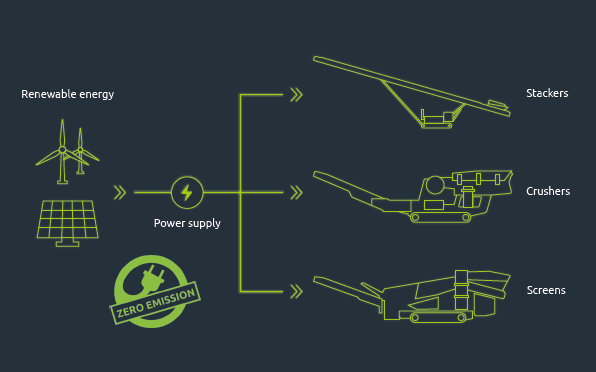

Keestrack introduced its ZERO-drive equipment at Bauma 2022, the first mobile crushing and screening equipment without any combustion engines on board. Electric motors drive most of the mobile crushing and screening equipment and power some necessary hydraulics systems.

Almost all equipment is available in ZERO-drive: all cone crushers, impact crushers including the new reversible horizontal impact crusher I4e, all scalper screens, the C6e classifier, all stackers, all jaw crushers except the B3 and the tracked Apron feeder A6. The ZERO-drive equipment can be powered by renewable energy in the most perfect situation but can also be powered by any generator.

Rupsmobiele diesel motor/generator

De rupsmobiele diesel motor/generator (M-serie) is in principe een rupsplatform met daarop de Keestrack motor/generatorunit. Hij is leverbaar met verschillende motoren zodat u voldoende vermogen bij de hand heeft.

De rupsmobiele diesel motor/generator kan een perfecte back-up zijn voor de ZERO-machines als deze ter plaatse geen elektrische plug-in mogelijkheid heeft. De eenheid heeft een standaard brandstoftank van 450 liter. Er kan een extra tank met een capaciteit van 2.000 liter op het platform worden geplaatst om de operationele tijd tot meerdere dagen te kunnen verlengen.